Building a robotics trainer from scratch? Yeah, that’s where things get tricky. You’ve got the design, the schematic looks good, but then comes the assembly part—and suddenly you’re staring at tiny components wondering if your hands are steady enough for 0402 resistors.

That’s basically why PCBSYNC exists.

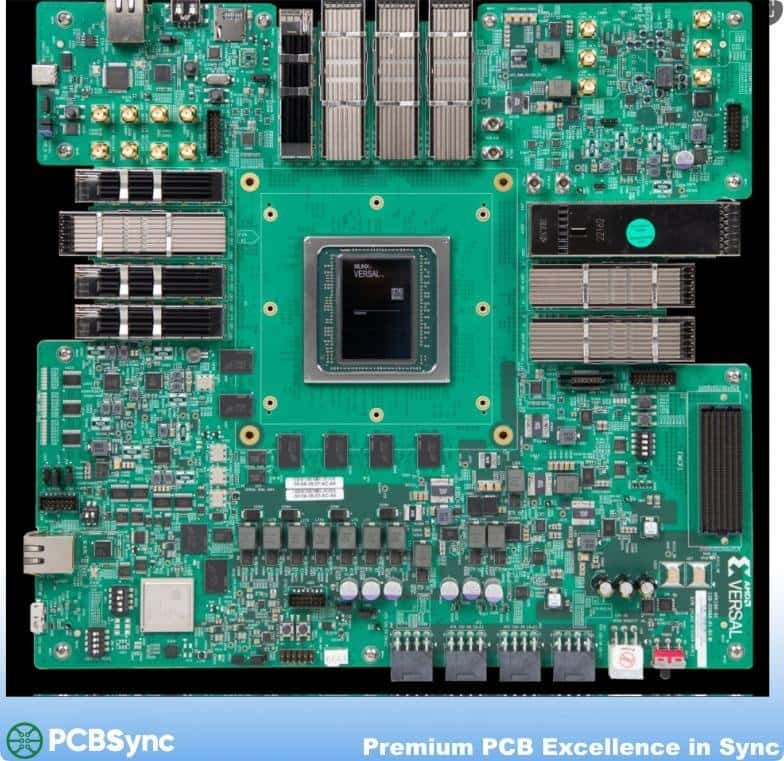

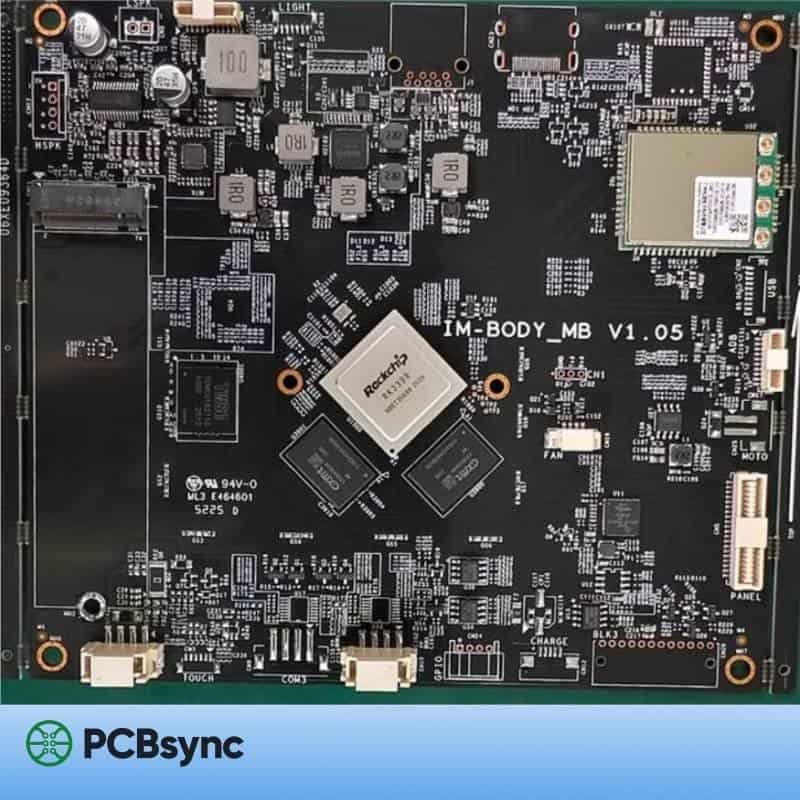

We handle PCB assembly for robotics trainers, which means educational kits, prototyping boards, motor driver circuits, sensor integration modules—all the stuff that goes into teaching people how robots actually work. Whether you’re a university setting up a new mechatronics lab or a startup creating your own training platform, we’ve got the production side covered.

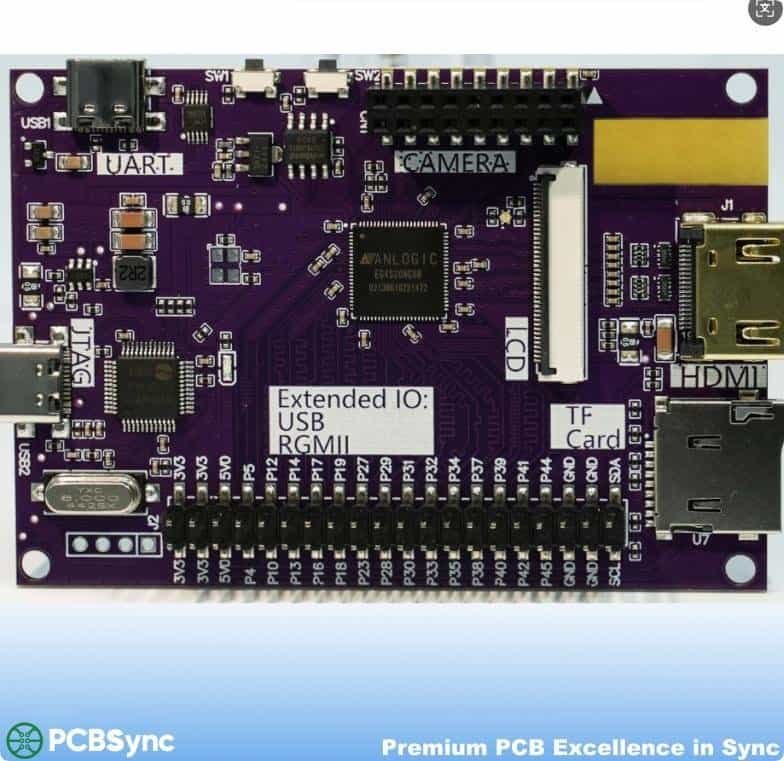

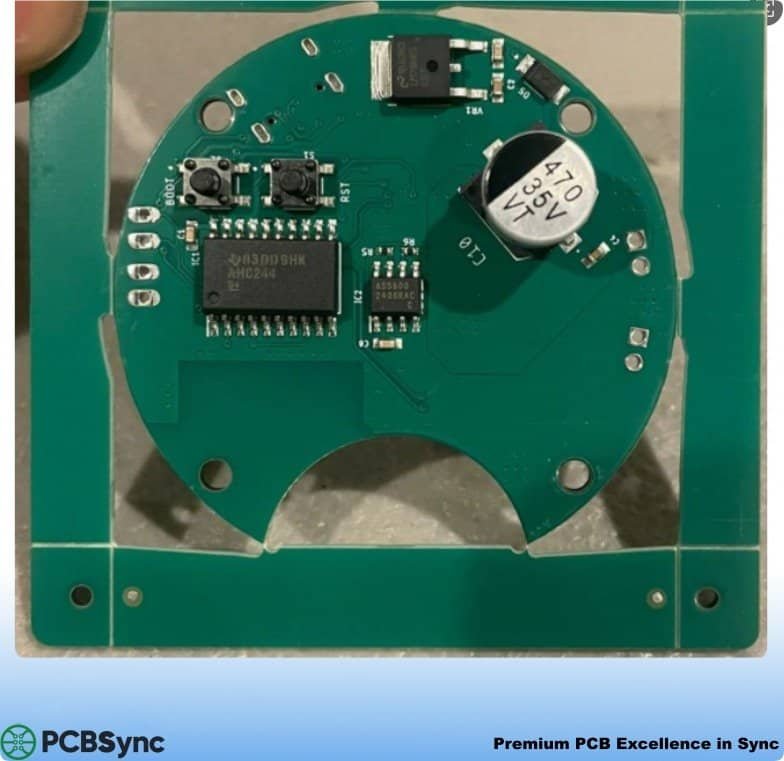

Here’s what we actually do: surface mount assembly, through-hole components, mixed technology boards. We work with common microcontroller platforms—your STM32s, ESP32s, Arduino-compatible chips—and can handle the motor driver ICs, sensor arrays, and communication modules that robotics trainers typically need. BOM sourcing is part of the deal too, so you’re not chasing components across five different suppliers.

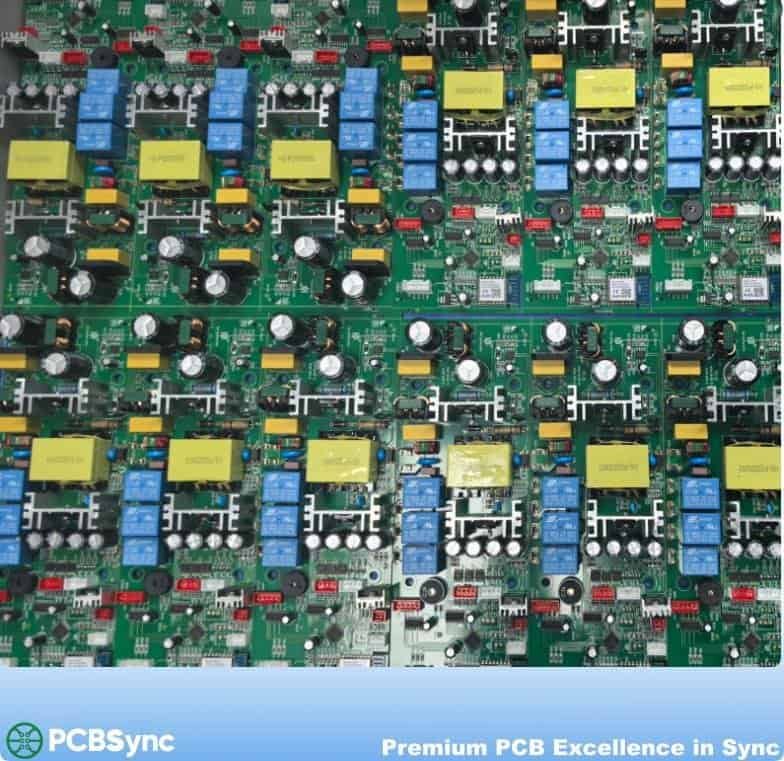

Quantities are flexible. Need 50 units for a classroom? Done. Scaling up to 500 for distribution? We can handle that without the pricing going completely sideways. Turnaround depends on complexity, but most standard assemblies ship within 2-3 weeks after design verification.

Quality control isn’t just a checkbox here. Every board gets visual inspection, and functional testing is available if you provide test protocols. Because honestly, nobody wants to debug 30 identical boards in front of frustrated students.

We’ve worked with educators, makerspaces, and EdTech companies who needed reliable assembly without enterprise-level minimum orders. If your robotics trainer project is sitting in design limbo because production feels overwhelming, maybe it’s time to talk.

Drop us your specs. Let’s see what we can build.