Building IoT devices isn’t easy. You need boards that actually work in the real world—compact, energy-efficient, and reliable enough to handle whatever connectivity protocols your project throws at them. That’s where PCBSYNC comes in.

We’ve built our IoT PCB assembly services around what developers and engineers actually need. If you’re working on smart home gadgets, industrial sensors, wearables, or any kind of connected device, we handle the assembly work so you can focus on making your product great.

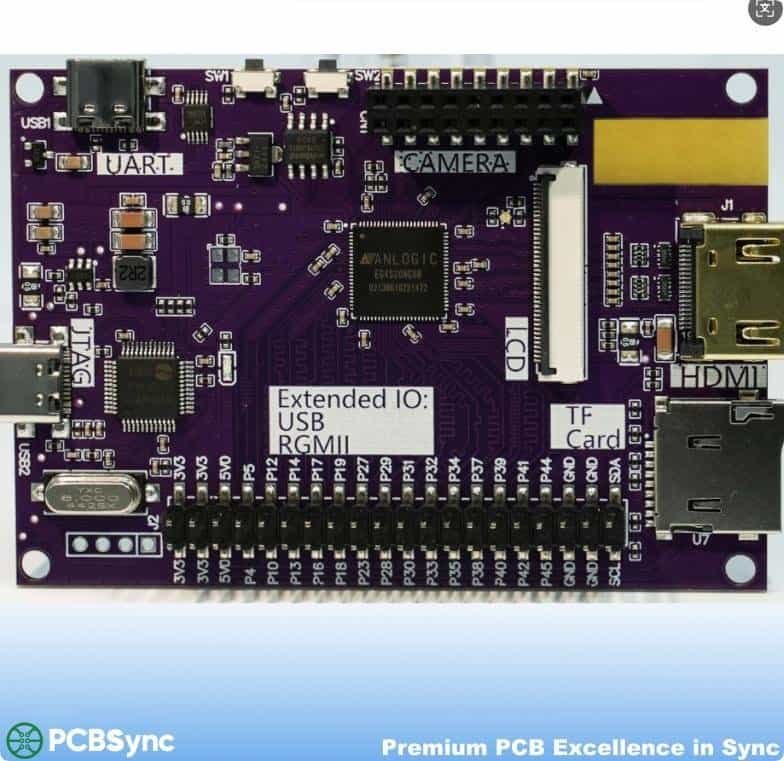

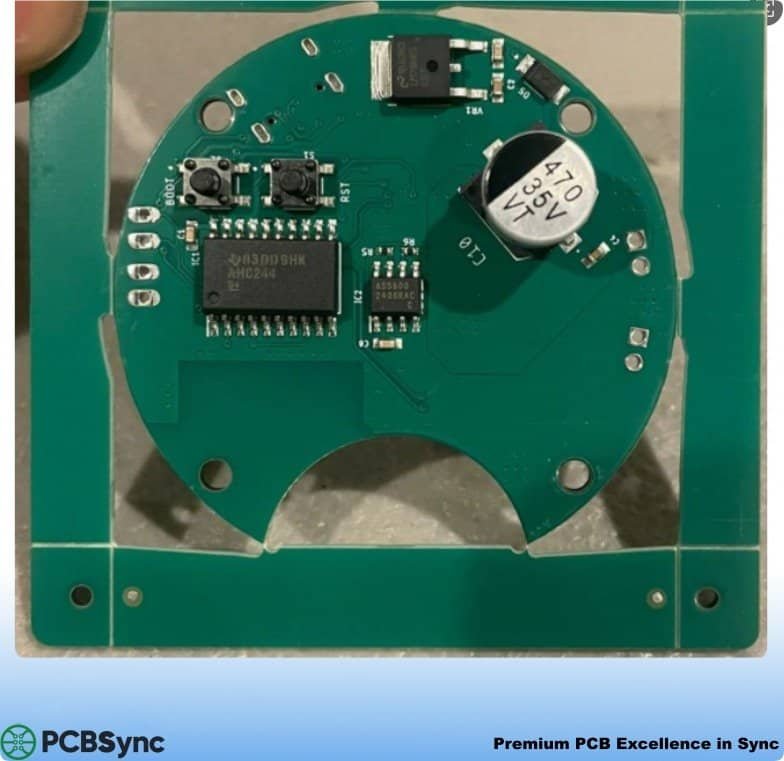

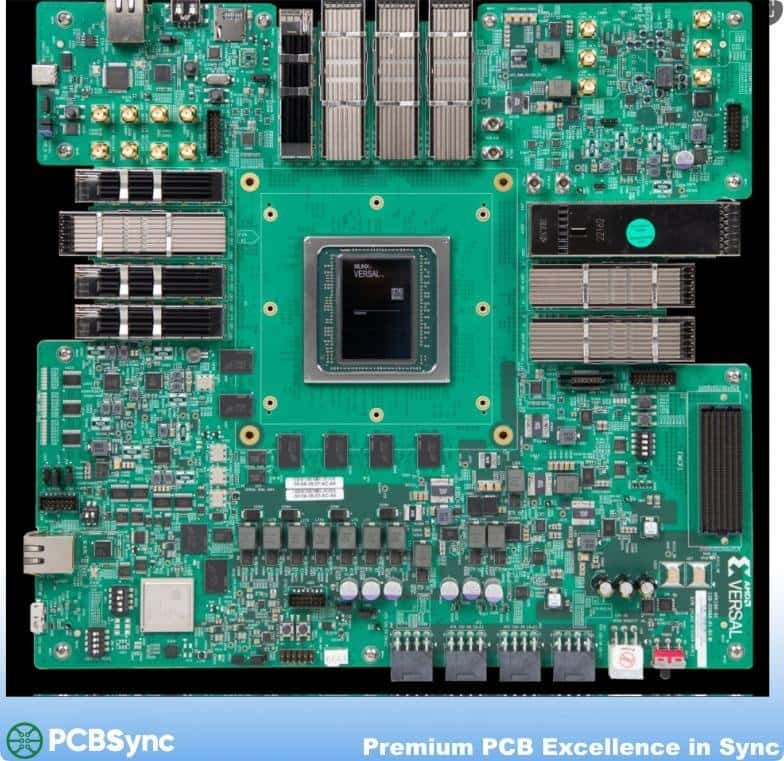

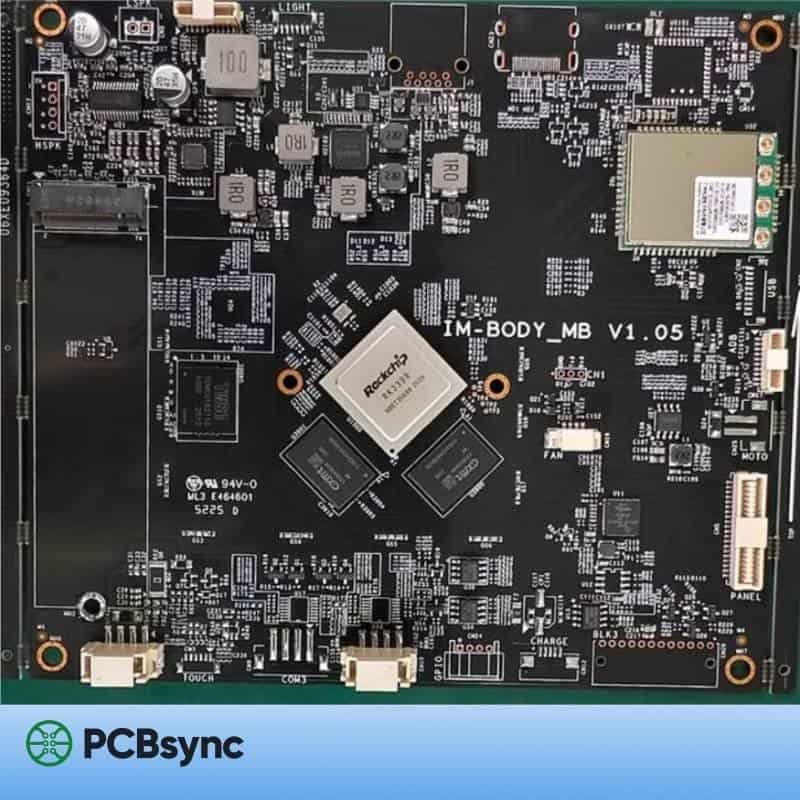

Our shop runs both SMT and through-hole assembly lines, and we’ve gotten pretty good at handling the tricky stuff—RF modules, Bluetooth chips, Wi-Fi components, microcontrollers, you name it. Multi-layer boards? No problem. We check everything with AOI systems, X-ray inspection when needed, and put assembled boards through functional testing before they leave our facility.

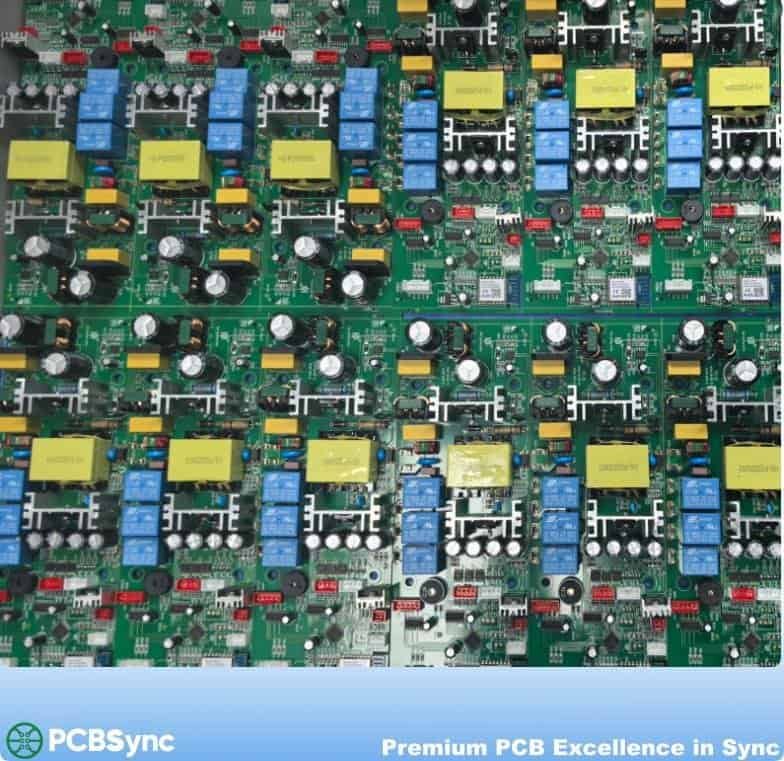

Here’s the thing about IoT projects: sometimes you need five prototypes by next week, sometimes you need five thousand units per month. We get that. Our production setup flexes between prototype runs and full-scale manufacturing without the usual headaches. We keep common IoT components in stock and have relationships with suppliers that actually respond when you’re in a pinch.

We also do DFM reviews if you want them. Before you commit to a design, we’ll take a look and point out anything that might cause problems during assembly or drive up costs. No charge for that—it saves everyone time and money down the road.

Quality matters, especially when your devices are going into people’s homes or running critical infrastructure. We maintain ISO certifications and run proper quality checks, but we’re not robotic about it. If something looks off, we reach out.

Bottom line: PCBSYNC handles IoT PCB assembly from prototype to production, with straight talk and reliable work. Let’s build something that actually ships.