Getting your fan controller boards assembled shouldn’t be a headache. PCBSync handles the entire process from bare PCB to fully populated board, so you can focus on what actually matters—getting your product to market.

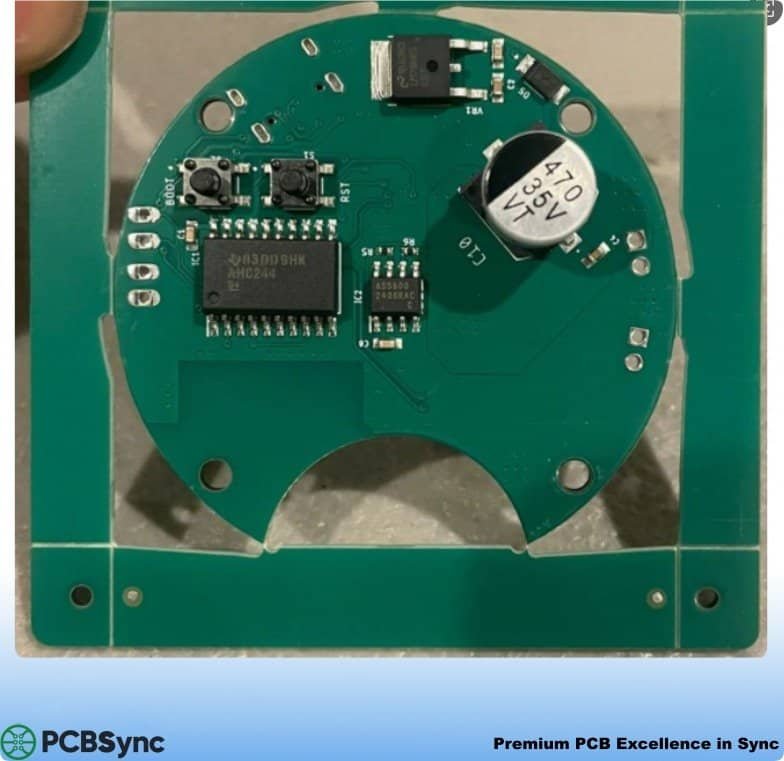

We’ve worked with thermal management designs ranging from simple single-fan controllers to complex multi-zone systems with PWM signal processing, temperature sensing circuits, and microcontroller-based logic. Our technicians understand the specific challenges these boards present: tight thermal tolerances, sensitive analog sections sitting next to noisy digital components, and the need for rock-solid reliability in applications where cooling failure means equipment damage.

The assembly process covers both SMT and through-hole components. We handle everything from tiny 0201 passives to chunky power MOSFETs and heatsink-mounted drivers. Our reflow profiles are optimized for mixed-technology boards, and we’ve got the hand-soldering expertise for those oddball connectors and wire-to-board terminations that fan controllers inevitably require.

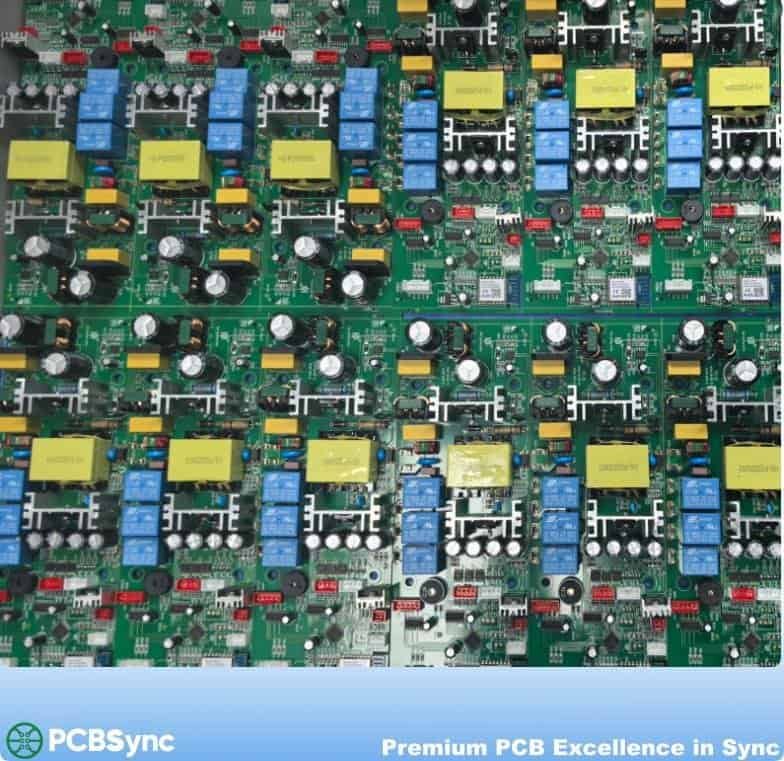

Quality control happens at multiple stages. AOI catches placement issues before they become expensive rework. Functional testing verifies that your PWM signals actually do what they’re supposed to do across the full duty cycle range. We can work with your test protocols or help develop custom fixtures if you need something specific.

Turnaround depends on your timeline and component availability. Standard lead times run two to three weeks for prototype quantities, faster if you’re in a bind and components are on hand. Volume production scales up without the growing pains—same quality standards whether you need ten boards or ten thousand.

Drop us your Gerbers, BOM, and pick-and-place files. We’ll review everything, flag any potential issues, and get you a quote within 48 hours. No mystery pricing, no surprise fees buried in the fine print.