When your project demands precision and your timeline leaves zero room for error, PCBSync delivers. We specialize in embedded control PCB board assembly—the kind of work where every solder joint matters and every component placement can make or break your product’s performance.

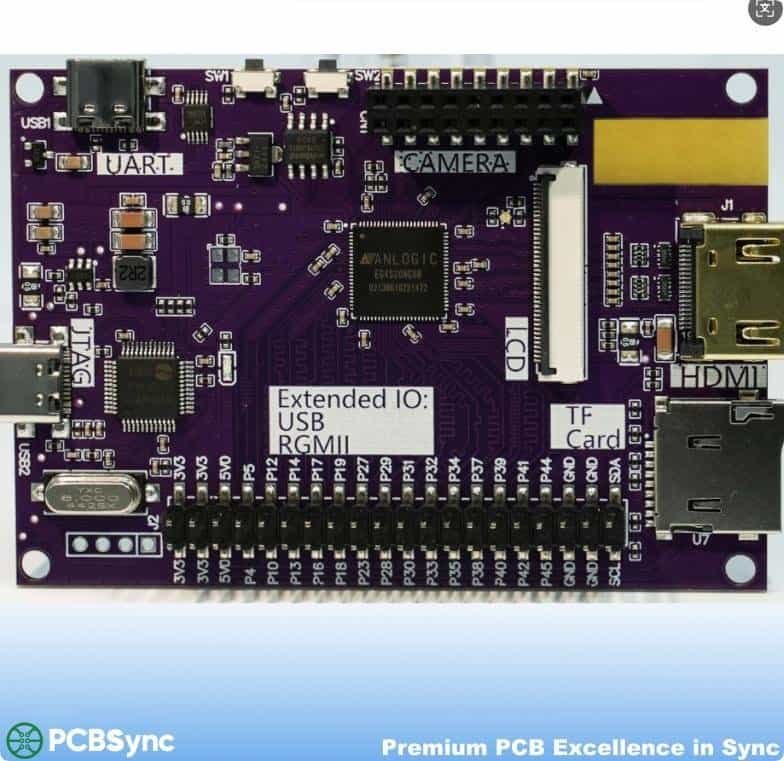

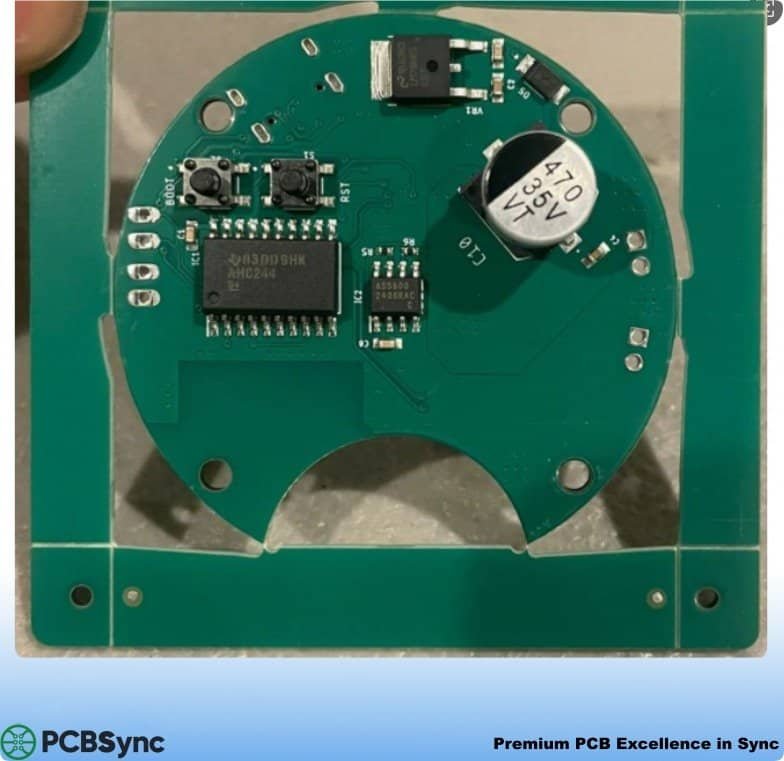

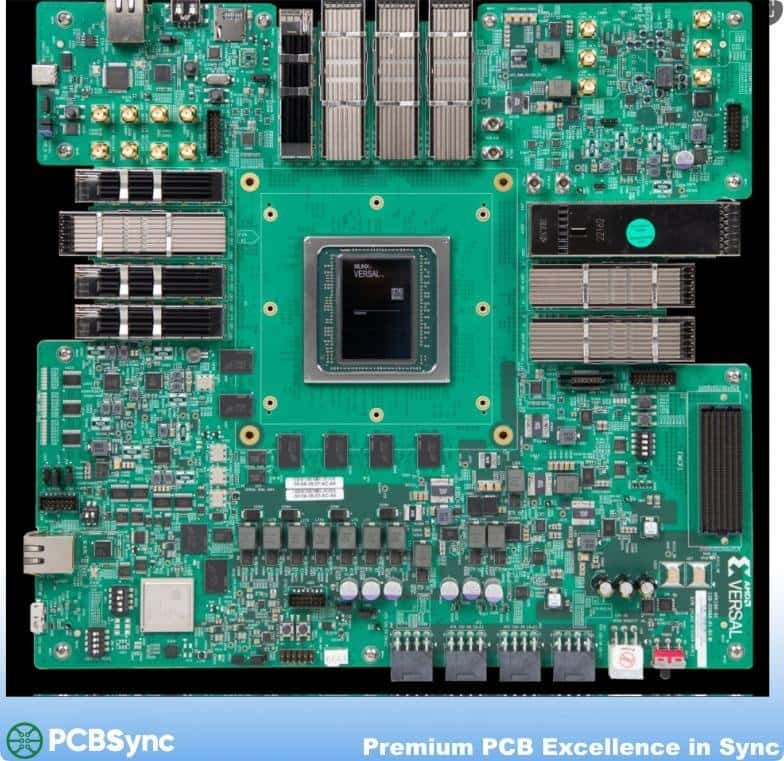

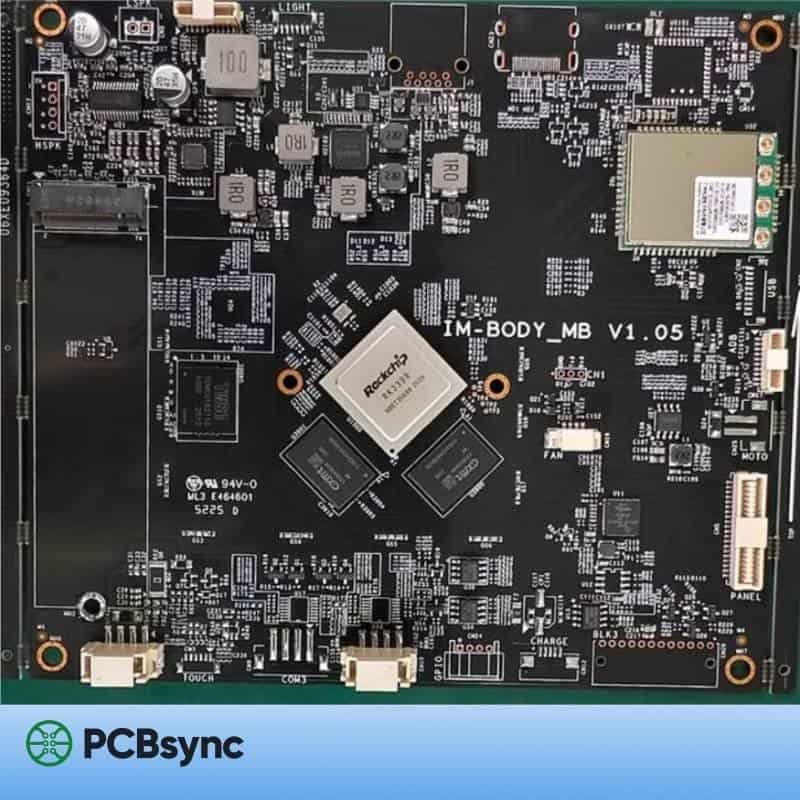

Here’s what we actually do: we take your designs from prototype to production-ready boards, handling everything from component sourcing to final testing. Our team works with microcontrollers, sensor interfaces, motor drivers, power management circuits, and communication modules daily. Whether you’re building industrial automation systems, IoT devices, medical equipment, or robotics platforms, we’ve seen similar challenges and solved them.

What makes embedded control boards tricky is the mix of analog and digital sections, tight noise margins, and the need for rock-solid reliability. We get that. Our engineers review your designs before assembly starts, flagging potential issues with thermal management, signal integrity, or manufacturability. Better to catch problems on paper than on a burned-out prototype.

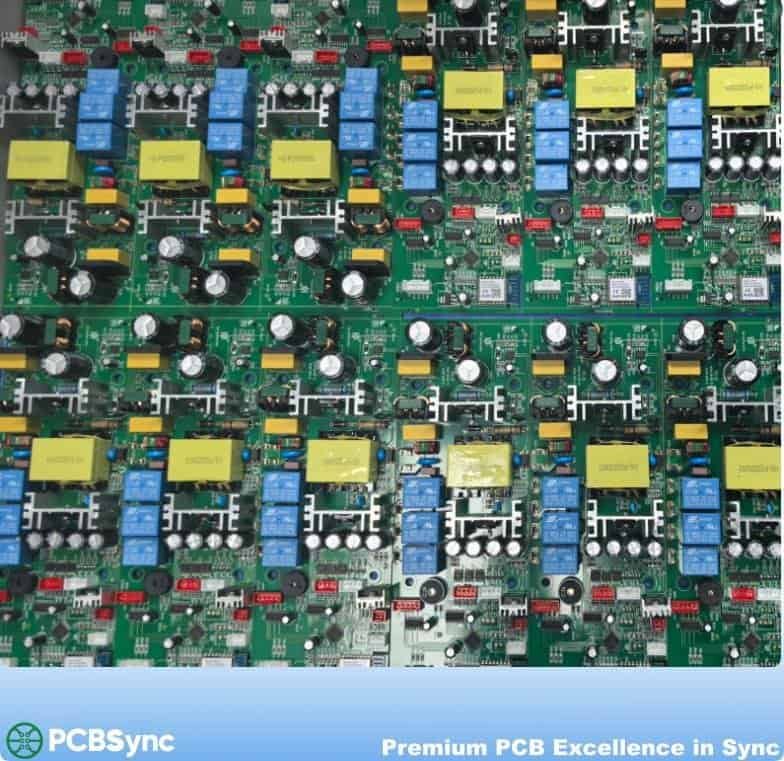

We handle surface mount and through-hole components, BGA packages, fine-pitch QFPs, and everything in between. Small batch runs for R&D? No problem. Scaling up to thousands of units? We’ve got the capacity. Each board goes through automated optical inspection and functional testing based on your specifications.

Turnaround times range from 48 hours for rush orders to standard two-week production cycles, depending on complexity and volume. We maintain relationships with major component distributors, which helps when you’re chasing down hard-to-find parts or dealing with supply chain headaches.

PCBSync isn’t trying to be the cheapest option out there. We’re aiming to be the team you trust when the board absolutely has to work the first time. Get in touch with your design files and let’s talk about what you’re building.