Getting your motor drive PCBs manufactured shouldn’t feel like navigating a maze. At PCBSYNC, we’ve stripped away the complexity and built our assembly services around what actually matters to engineers and product teams.

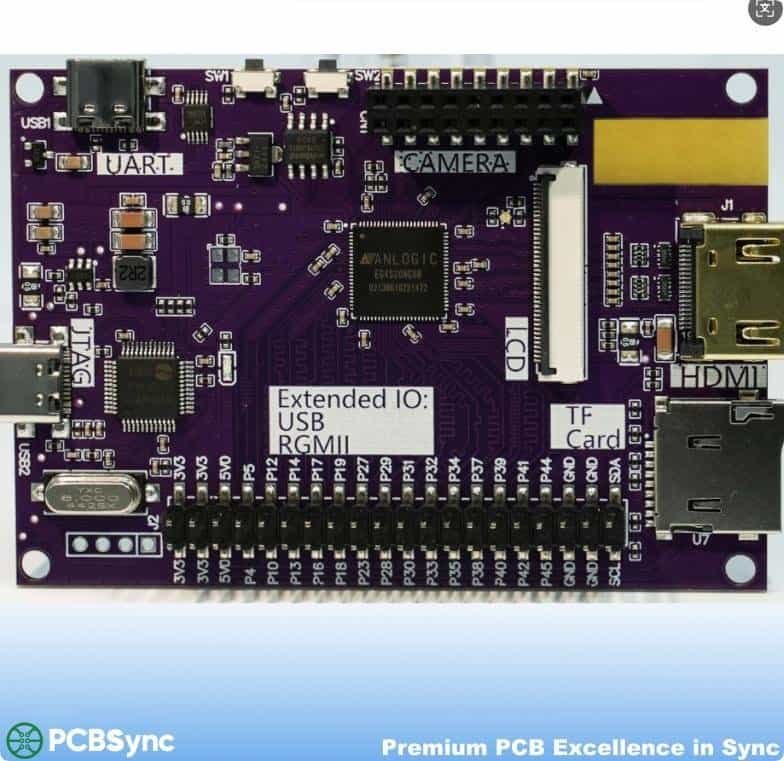

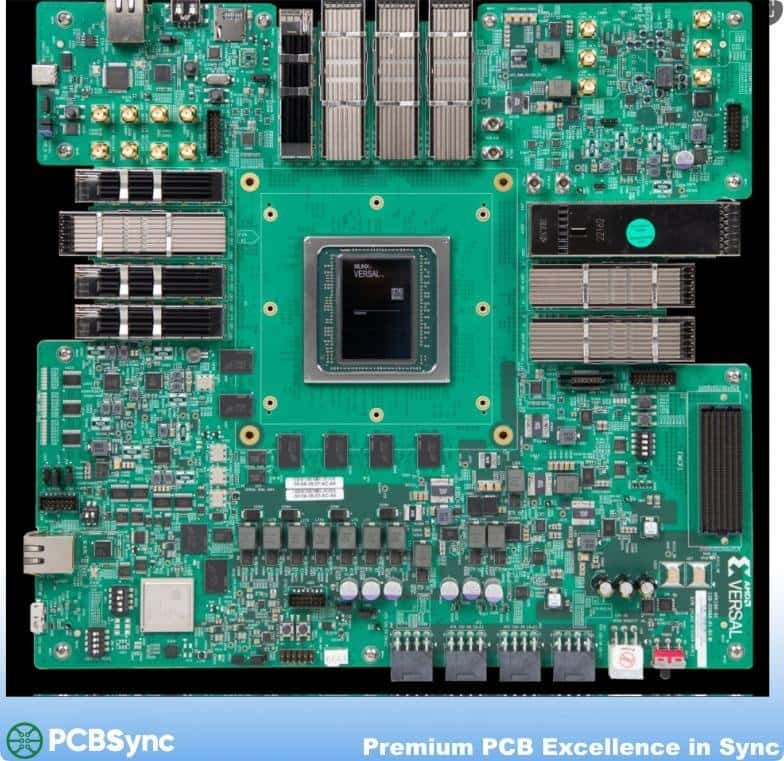

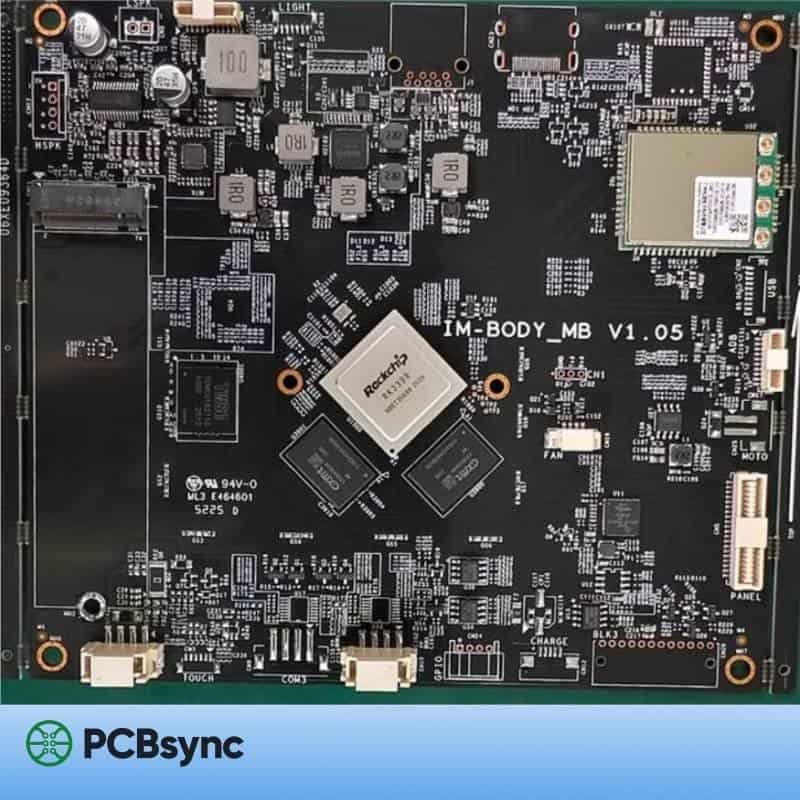

We handle motor drive PCB assemblies from prototype to production. Whether you’re working on BLDC controllers, servo drives, or industrial motor applications, our team knows these boards inside out. The components that make motor drives tricky—high-current traces, thermal management zones, precision analog sections—we deal with them every day.

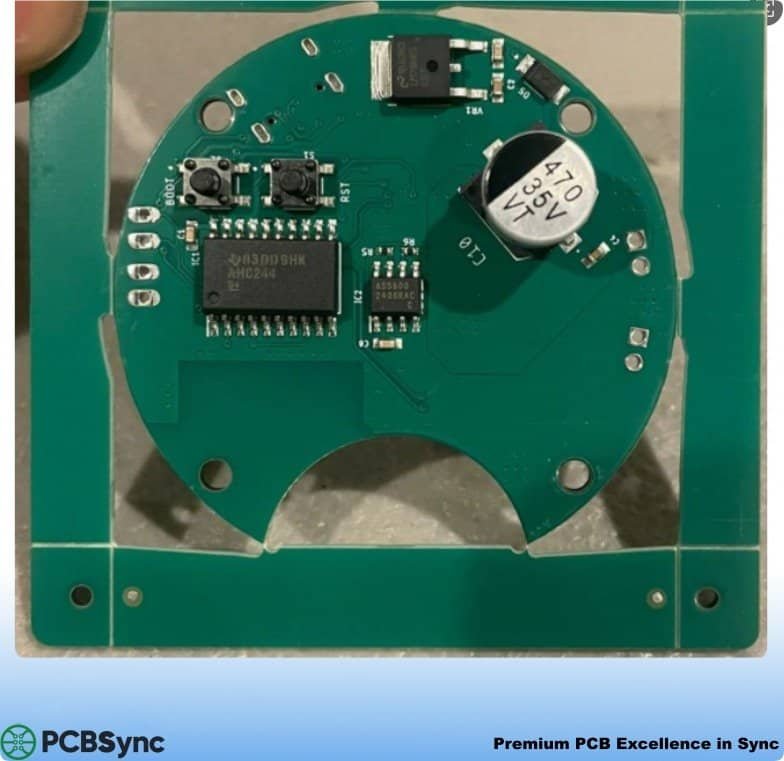

Our assembly line handles both SMT and through-hole components, which matters because motor drives typically need both. Power MOSFETs, gate drivers, current sense resistors, bulk capacitors—we place them with the accuracy your design demands. And yes, we actually test for proper thermal relief and adequate clearances during assembly, not just assume your files are perfect.

What sets us apart? Speed and communication. You’ll get real DFM feedback within hours, not days. If we spot something that might cause issues—maybe a trace that’s cutting it close for your current rating, or a component placement that could create thermal problems—we’ll flag it immediately. No waiting around for a quote revision cycle.

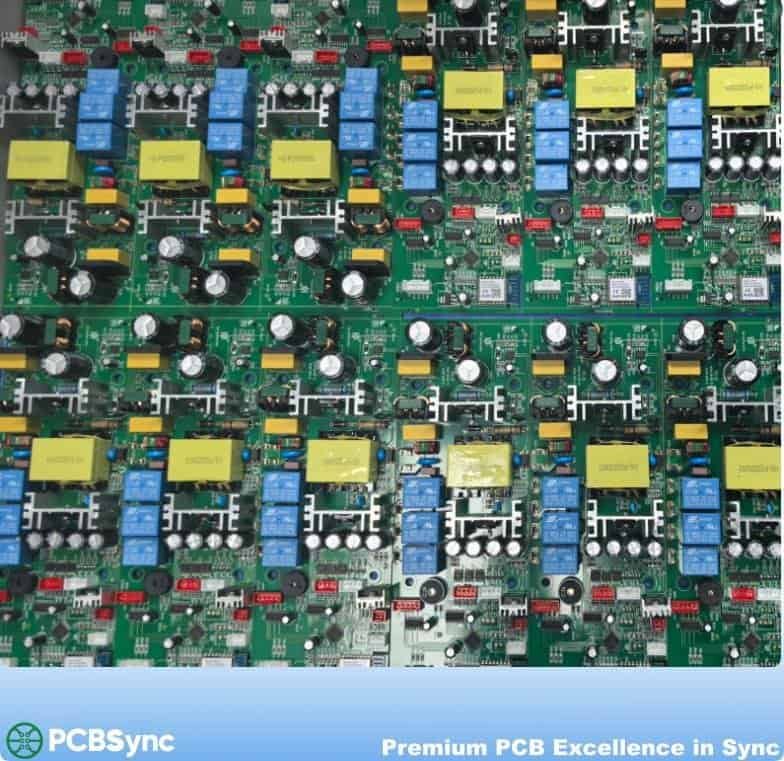

We also understand that motor drive projects often live in that awkward space between prototype and full production. You might need 50 boards now and 5,000 later. Our pricing and process scales with you, so you’re not penalized for starting small or forced to order thousands before you’re ready.

Quality checks include AOI inspection, functional testing setups for motor drives, and proper handling of high-voltage sections. We’re ISO certified, but more importantly, we ship boards that work the first time.

Upload your Gerbers, get a quote in under 24 hours, and let’s build something that spins properly. That’s the PCBSYNC approach—straightforward, reliable, and focused on getting your motor drive designs into production.