When it comes to medical device manufacturing, there’s no room for shortcuts. PCBSYNC understands that the circuits powering diagnostic equipment, patient monitors, and surgical instruments need to meet standards that go beyond typical electronics assembly.

We’ve built our medical PCB assembly services around the reality of what healthcare technology demands. Every board we produce goes through rigorous quality checks because we know these components end up in devices that doctors and patients rely on daily. Our facility maintains ISO 13485 certification, and our team stays current with FDA regulations and IPC standards specific to medical electronics.

What sets our approach apart is the attention we give to traceability. From component sourcing to final testing, we document everything. If there’s ever a question about a batch or a specific board, we can trace it back through every step of the assembly process. This isn’t just paperwork—it’s the kind of accountability that medical device manufacturers need when they’re seeking regulatory approval or managing their supply chain.

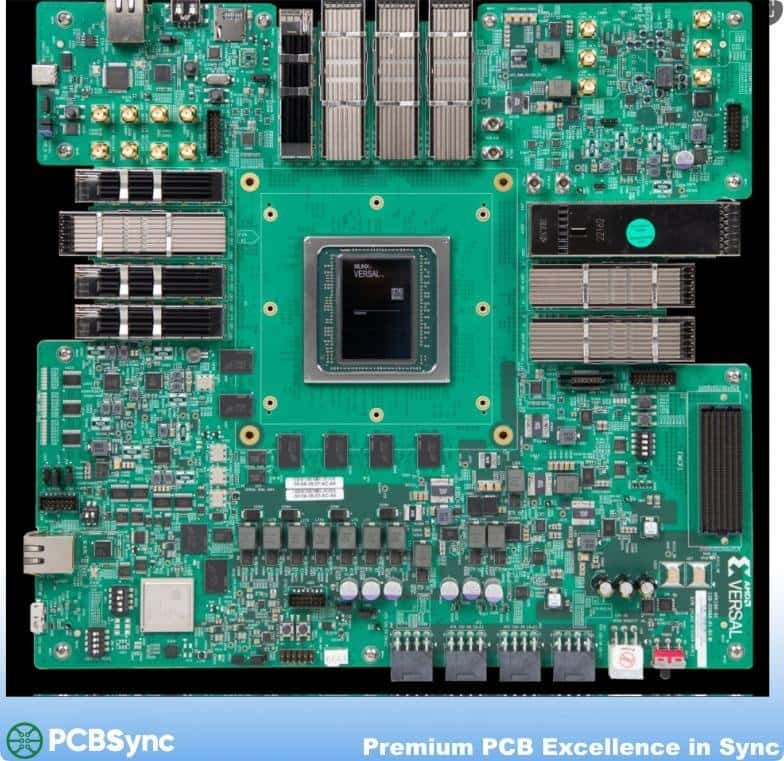

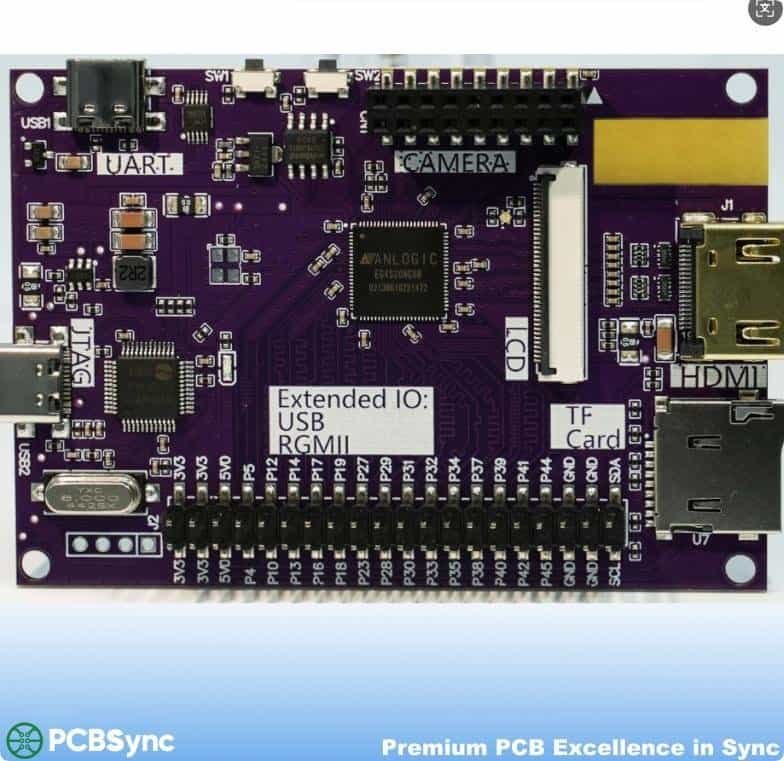

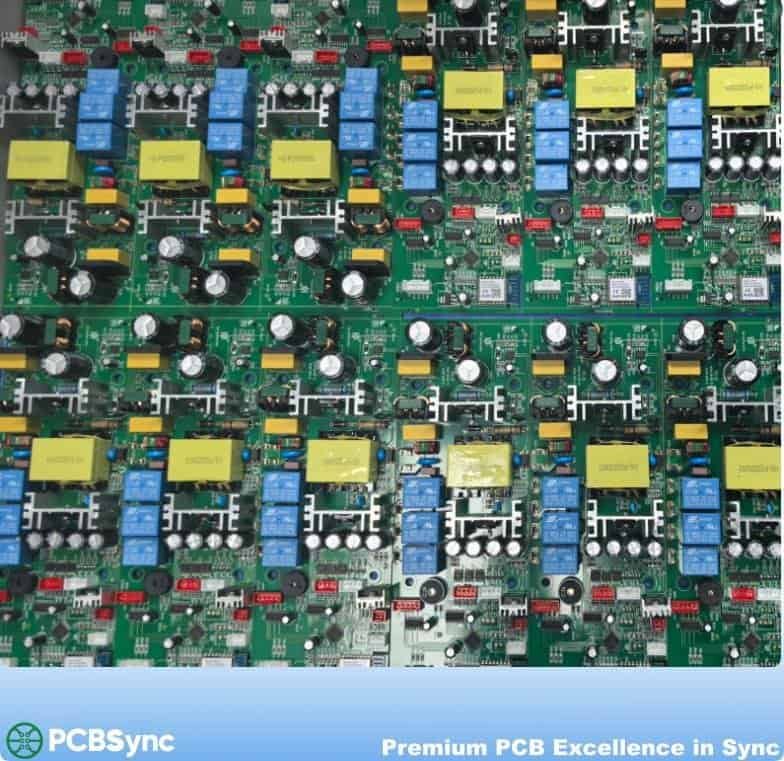

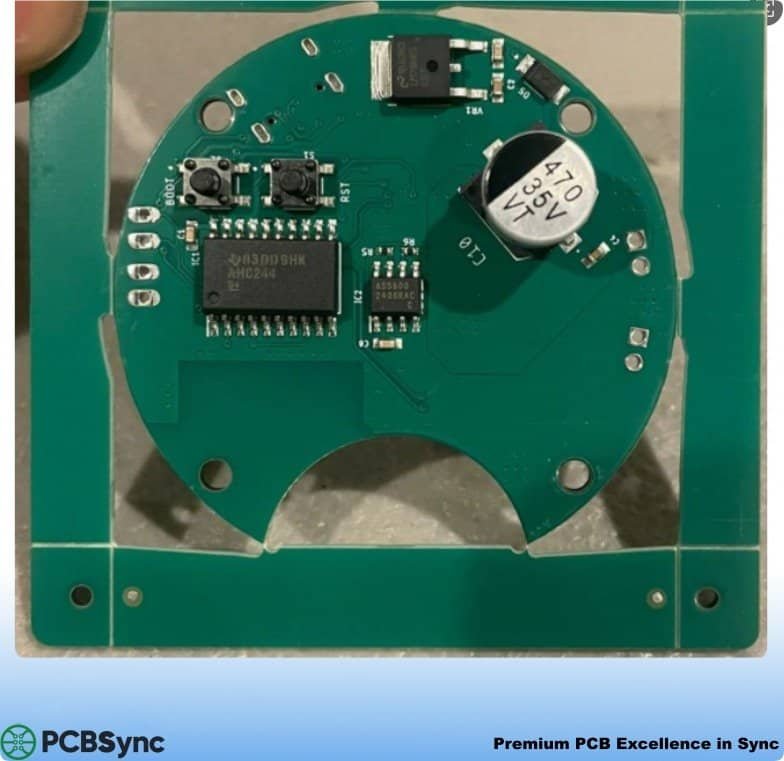

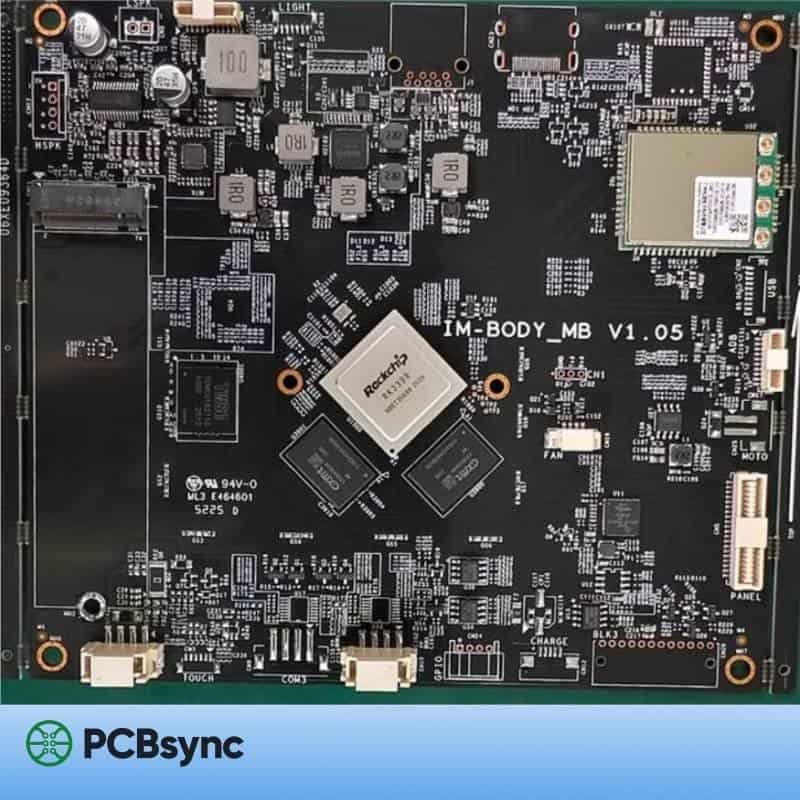

Our assembly capabilities cover the full spectrum: multilayer boards, fine-pitch components, BGA placement, and conformal coating for devices that need protection from bodily fluids or sterilization processes. We handle prototypes for startups developing their first device and production runs for established companies shipping thousands of units monthly.

The engineers on our team have seen plenty of complex designs. They’ll flag potential manufacturability issues early and work with you to solve them before they become expensive problems on the production floor. We also understand that medical projects often have tight deadlines tied to clinical trials or product launches, so we’ve structured our operations to be responsive without sacrificing quality.

PCBSYNC brings together the technical precision and regulatory awareness that medical PCB assembly requires, delivered by people who actually care about getting it right.