PCBSYNC offers specialized assembly services for Rogers printed circuit boards, catering to the demanding requirements of high-frequency and high-performance electronic applications. Rogers PCBs are renowned for their superior electrical properties, making them the preferred choice for RF/microwave circuits, automotive radar systems, aerospace applications, and advanced telecommunications equipment.

The company’s Rogers PCB assembly capabilities encompass a comprehensive range of materials from the Rogers Corporation portfolio, including the popular RO4000 series, RO3000 series, and RT/duroid laminates. These materials provide exceptional dielectric constant stability, low loss tangent, and reliable performance across extreme temperature ranges, which are critical factors for applications operating at high frequencies.

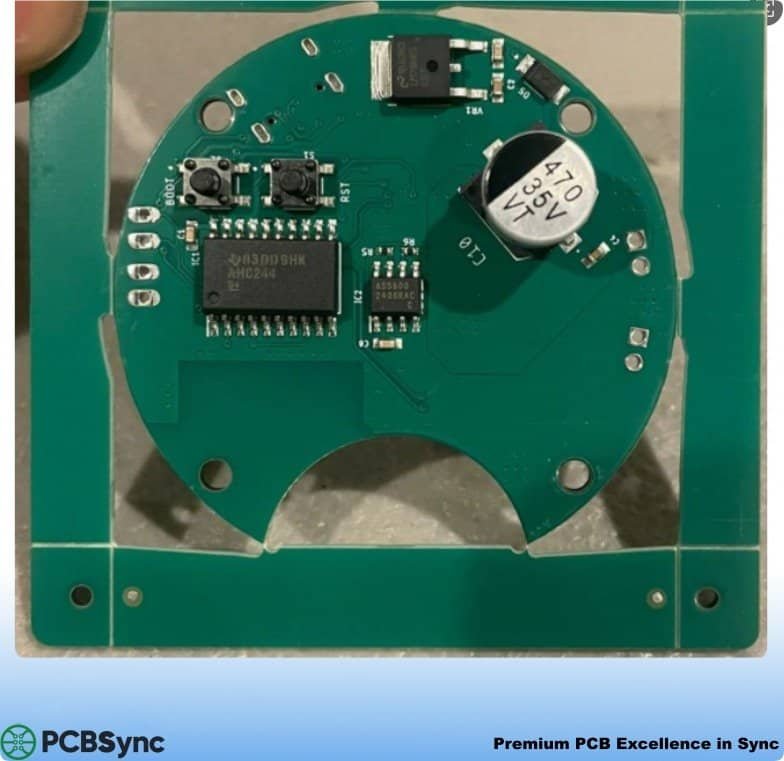

PCBSYNC’s assembly process for Rogers PCBs requires specialized expertise due to the unique handling characteristics of these materials. Unlike standard FR-4 boards, Rogers laminates demand precise temperature control during soldering, careful handling to prevent delamination, and specific drilling parameters to maintain material integrity. The company’s experienced technicians understand these nuances and employ advanced assembly techniques to ensure optimal results.

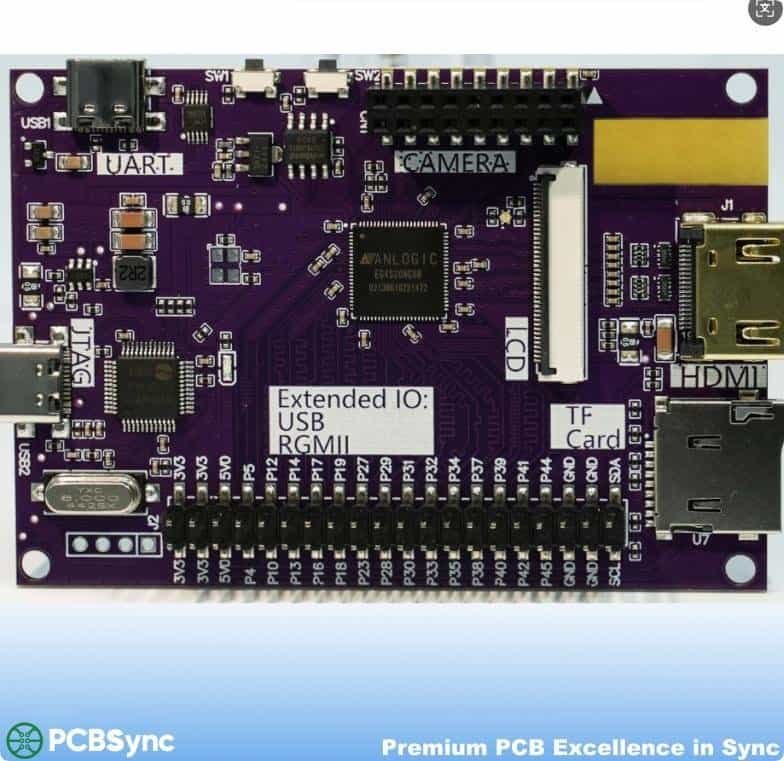

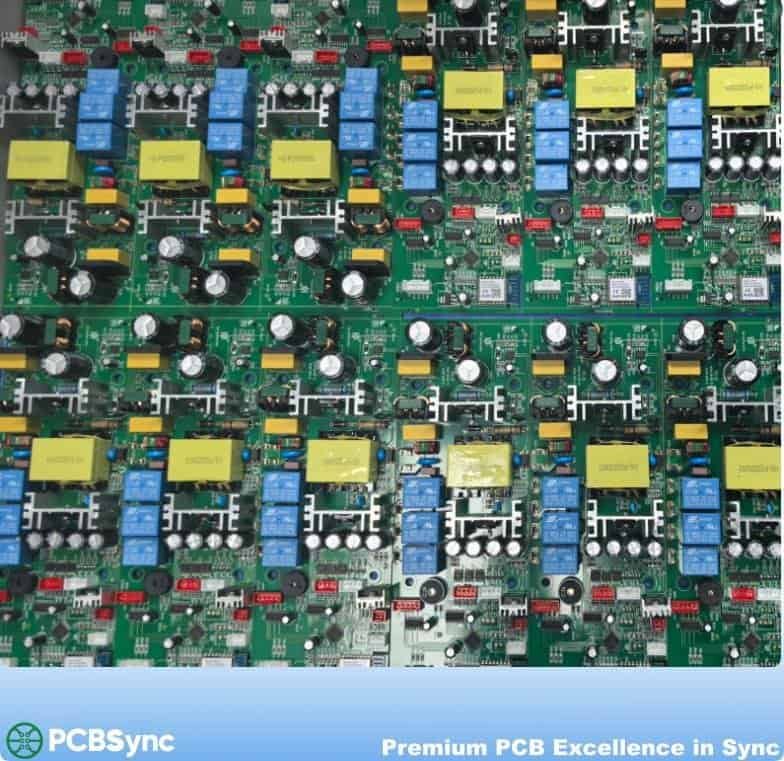

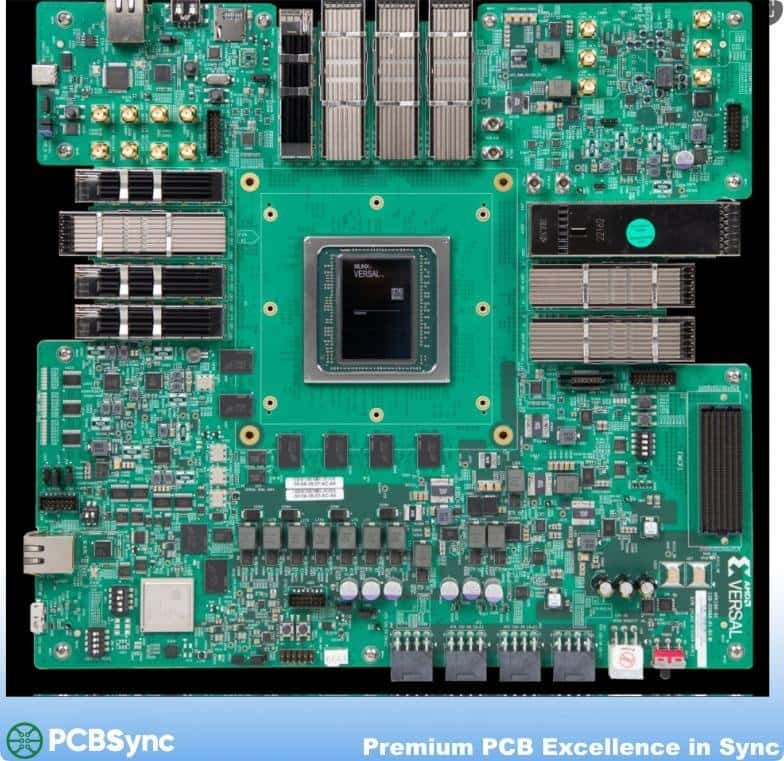

The service offering includes both surface mount technology (SMT) and through-hole assembly, accommodating complex designs with tight tolerances. PCBSYNC utilizes state-of-the-art equipment calibrated specifically for Rogers materials, ensuring precise component placement and reliable solder joints. Their quality control procedures include automated optical inspection (AOI), X-ray inspection for hidden connections, and rigorous testing protocols to verify electrical performance.

For customers in industries such as 5G communications, satellite systems, military defense, and medical devices, PCBSYNC provides turnkey solutions from prototype to production volumes. Their engineering support team assists with design for manufacturability (DFM) reviews, helping clients optimize their Rogers PCB layouts for assembly efficiency and performance.

With competitive lead times and a commitment to quality, PCBSYNC positions itself as a trusted partner for organizations requiring reliable Rogers PCB assembly services that meet stringent industry standards and performance specifications.